Duramica Reinforced Panels: Enhanced Strength and Beauty of Blue Onyx for Versatile Applications

- gpgrantswiss

- Oct 30, 2024

- 3 min read

Updated: Mar 15

What is Blue Onyx?

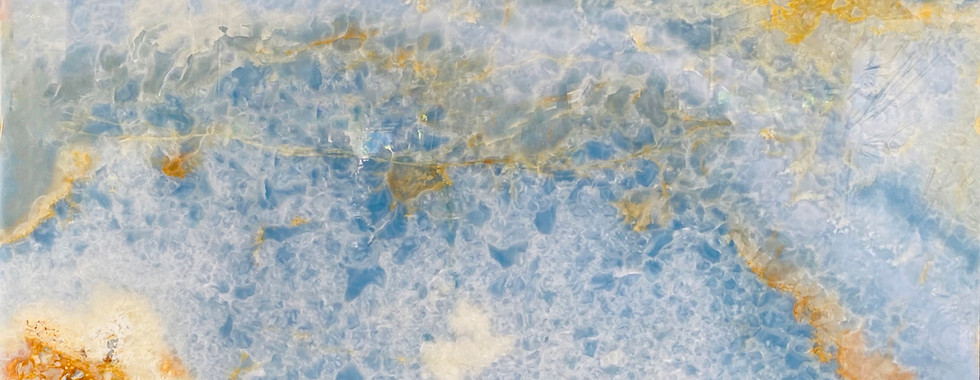

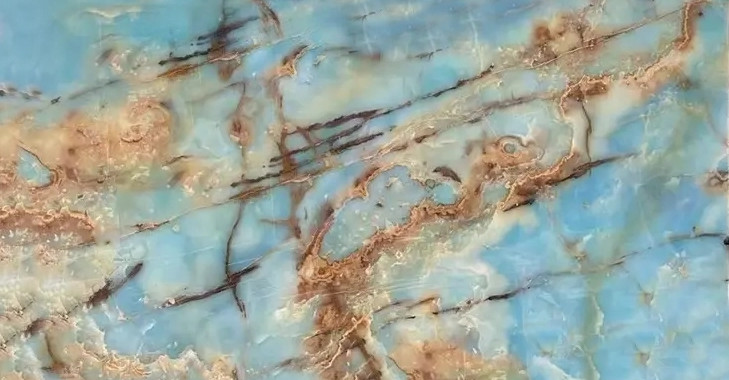

Blue Onyx is a distinctive variety of chalcedony with a deep blue color that ranges from light to dark shades, often layered in striking bands. This unique gemstone is primarily sourced from Argentina, Mexico, Pakistan, Iran, and also found in China, Italy, and Turkey. Its beauty and visual appeal make it an excellent choice for decorative uses, though it requires special care due to its delicate nature.

Characteristics and Challenges of Blue Onyx

Visual Appeal: Genuine Blue Onyx displays various shades of blue, often with intricate bands or layers that enhance its aesthetic appeal. When polished, it has a smooth, glossy surface, though matte or honed finishes are also available.

Durability and Hardness: With a Mohs hardness rating of 6.5 to 7, Blue Onyx is softer than materials like marble and granite. This softness makes it prone to scratches and chips, which can lead to technical waste during installation as fractures and chipping often occur, especially with larger slabs.

Easy Installation and Maintenance with Duramica Reinforced Onyx Panels

To address these fragility challenges, Duramica has developed different types of reinforced stone veneer Blue Onyx panels, engineered for easy installation and enhanced durability.

Duramica DuraSkin (Ceramic Base): DuraSkin’s natural stone veneer sits on a ceramic base, making it lightweight and resilient. Stone veneer panels are ideal for interiors.

Standard formats: 300 x 600 mm ≤, 1200 x 600 mm ≤ / Large formats: 2400 x 1200 mm ≤

Stone thickness: 3 mm ≥ / Large formats stone thickness: 5 mm ≥

Ceramic base thickness: 9 mm / Large format ceramic base thickness: 9 mm, 12 mm

Weight (kg/m²): ± 36-37,5 kg / ± 43 kg

Duramica DuraMet (Aluminum Honeycomb Base): Utilizing an aluminum honeycomb core, DuraMet is one of the lightest stone panels available, suitable for walls, ceilings, and decorative columns.

Standard formats: 2400 x 1200 mm ≤

Stone thickness: 5 mm ≥

Base thickness: 15, 20, 25 mm

Weight (kg/m²): ± 14-16 kg

Duramica Glassonyx (Backlit Glass Base): This composite combines an ultra-thin Blue Onyx layer with a backlit glass base, creating a glowing, translucent effect.

Glassonyx Fibreglass is a ultra-lightweight composite with large-size natural stone based on backlit cellular fibreglass.

Backlit Onyx Standard formats: 2400 x 1200 mm ≤

Stone thickness: 5 ≥

Base thickness: 15, 20 mm

Weight (kg/m²): ± 11, 16 kg

It is possible to produce a triplex structure, where the stone is between a glass base and a top coating of safety glass - Duramica Glassonyx Triplex. This product allows onyx and other translucent stones to be used on floors or in aggressive areas such as swimming pools, steps, bars etc.

Stone Surfaces

Lightweight stone panels are available in different surface finishes, for example:

Polished Finish: The polished finish enhances the natural beauty of Blue Onyx, creating a high-gloss, reflective surface that brings out the depth of color and intricate banding. This finish provides a luxurious look, making it ideal for spaces where the stone serves as a focal point, accentuating its bold patterns and vibrant hues. The smooth, mirror-like surface also adds a touch of elegance, suitable for upscale interiors.

Honed (Matte) Finish: The honed, or matte, finish presents a softer, satin-like texture, reducing reflections and offering a more subdued look. This finish is perfect for spaces that require a more understated aesthetic, balancing elegance with subtlety. The honed surface is also practical, as it minimizes the visibility of small scratches, making it a low-maintenance option suitable for various interior settings.

Types of Blue Onyx Varieties

Azure Obscura Onyx

Onyx Blue Aqualith

Blue Onix Azzurro Mexico

Aqua Gold Blue Onyx Pakistan

Cielo Del Sahara Blue Onyx

Antofagasta Azul Blue Onyx Argentina

Other Types of Blue Onyx

Blue Onyx Decorative Wall Panels: Summary

Duramica’s reinforced panels allow the beauty of Blue Onyx to be enjoyed in a wider variety of settings, providing durability and easy handling during installation. The material’s lightweight nature simplifies installation, and its maintenance is effortless, making it an ideal choice for intricate architectural details. On-site cutting and shaping are straightforward, minimizing waste and technical damage. The reduced risk of chipping and straightforward on-site processing make these panels an excellent choice for applications demanding both aesthetics and resilience.